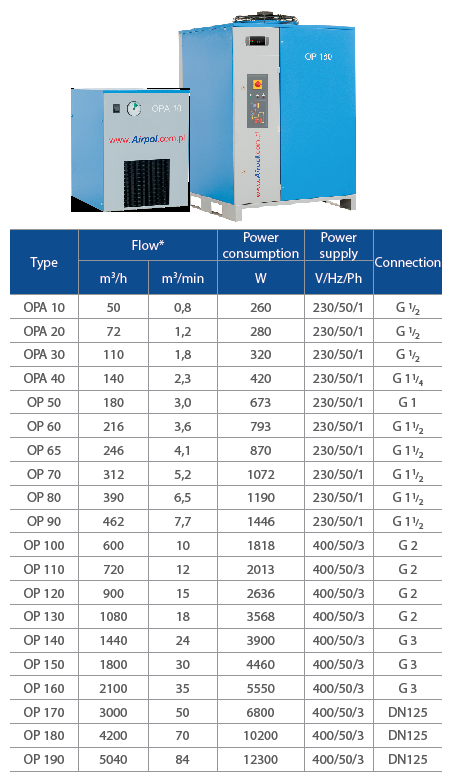

Refrigerated air dryers

The refrigerant dryers are designed to remove water, moisture and vapour, having destructive and corrosion influence on the networks and pneumatic tools, from compressed air.

The compressed air at average temperature of +30oC ÷ +45oC supplied to the dryer, is initially cooled in the air to air heat to +14oC ÷ +23oC. Then the air is further cooled in the evaporator of the refrigerant circuit and achieves the set dew point of +3oC, required to condensate water vapour existing in the compressed air circuit.

The use of dried compressed air makes it possible to limit the corrosion risk of tools, cylinders, pneumatic machines, air receivers, pipelines and also avoid damage of the final product e.g. paint coating.

- Reliability

- 24/24 continuous duty

- Simply design, easy maintenance

- Safe operation in tropical weather

- Environment friendly refrigerant

- High efficiency of water separation

- Digital display

- Electronic water valve built-in, controlled by level of condensate

- + Effective prevention off all compressed air loss

- + Discharge only water, NOT Compressed air = Energy Savings